EnerBurn Information

How EnerBurn Works

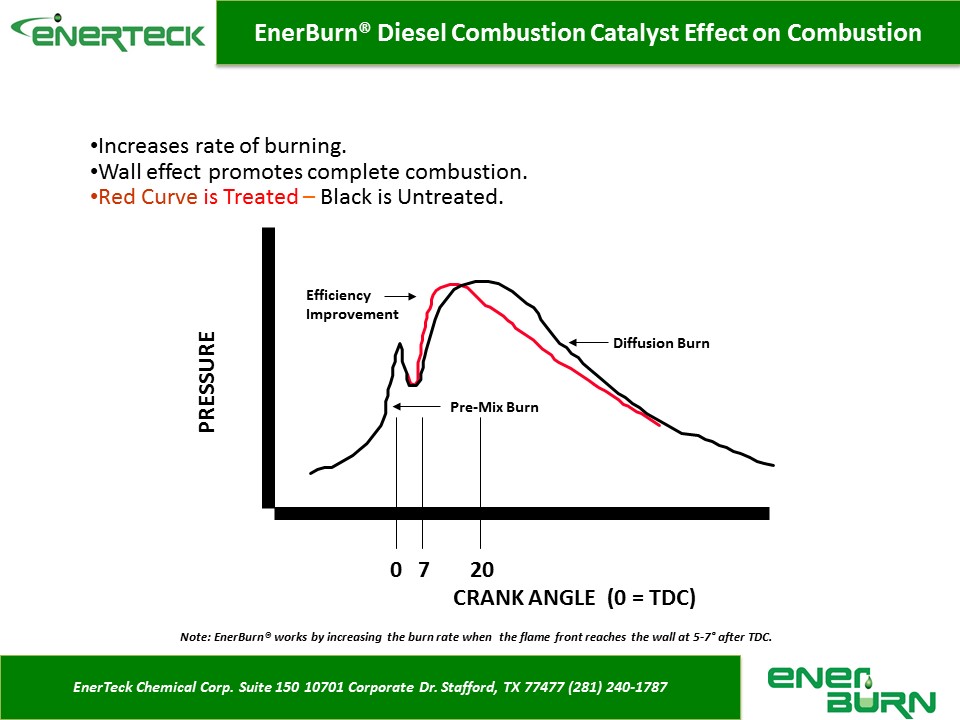

EnerBurn® works by conditioning the combustion chamber surfaces with a nano-scale catalytic coating that doubles the rate of combustion of the fuel molecules. This causes higher pressure earlier on crank angle which allows the engine to produce more work (HP) with the same amount of fuel. With the work load being the same, this translates into greater fuel efficiency (gph). The increased work conversion, due to earlier pressure on crank angle, results in a reduction of the exhaust temperature of the engine by approximately 40-44 degrees F.

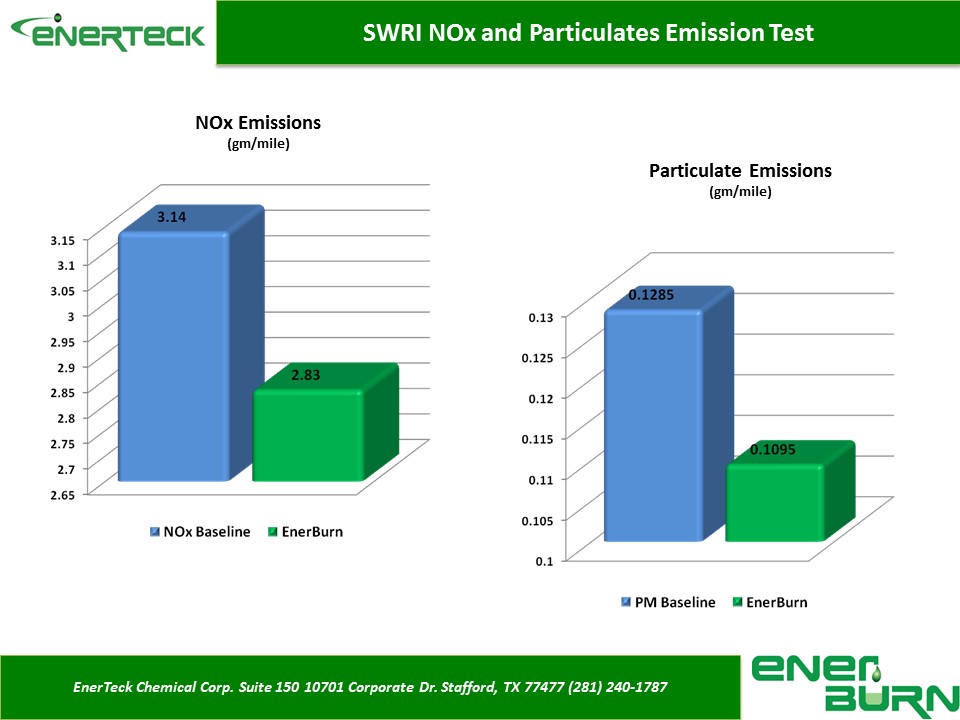

A decrease in fuel consumption, substantial improvement of DPF's and an overall increase in fuel burn efficiency translate to substantial emission reductions as well. The emission benefits are achieved due to a

- More Complete Combustion

- Lower Operating Temperature

- Lower Overall Engine Pressure

2-stroke diesel engine with EnerBurn catalytic coating area shown (orange shading)

2-stroke diesel engine with EnerBurn catalytic coating area shown (orange shading)

Proving The Benefit

Depending on the application, we have a variety of field trial protocols to evaluate the EnerBurn technology in real-life work environments, using your equipment and under your normal operational environments. Proving the product works as advertised under your normal workload is far more important than a lab or bench testing protocol and is a benefit to both you, the customer, and Enerteck.

Since EnerBurn® is a catalyst and NOT AN ADDITIVE, (although our delivery method to the engine is via the diesel fuel) a period of time is required for the catalytic effect to build up. The time required for the catalyst to properly condition the engine, which we refer as the “Conditioning Period”, will vary for each different type of engine application and is based on hours of use.

Different diesel engine applications require slightly different protocols. Each piece of equipment to be evaluated, is base-lined prior to treatment with the EnerBurn® Diesel Fuel Catalyst, treated for the required period of time and then benchmark tests are performed when the evaluation period is over. Benchmark results are then compared with the baseline numbers to determine the performance effect the EnerBurn® catalyst produced. Baseline readings include, but are not limited to

- Engine Temperature

- Oil Pressure

- Fuel Consumption (at variousloads, usually idle, mid-range, standard load, full throttle)

- SHP (shaft horsepower) (at various loads, usually, idle, mid-range, standard load, full throttle)

- Shaft torque

- Emissions

Product Implementation

Implementation of the EnerBurn catalyst is easy and essentially maintenance free. There are three ways you can begin using the EnerBurn technology.

- Fuel delivered pre-treated with EnerBurn

- Hammonds chemical injection equipment installed at your fuel tank/tanks

- Hand treating on your tank site when fuel is delivered (Not recommended)

Pre Treated Fuel

Certainly, the easiest and most efficient method is to have pre-treated fuel delivered to your fuel tanks. We will work with your fuel suppliers to determine if we can arrange for pre-treated fuel to made available to you.Chemical Injection Systems

Our chemical injection systems, supplied by Hammonds, are military grade and last for many, many years. Our units in the field since 2009 have yet to require service, including all marine units which operate in harsh environments. Permitting is required for most injection unit installation, which adds some time to the installation process. Once these units are functional, they require minimal maintenance. Telemetry is an available option on these units, which we recommend. Telemetry allows both you and Enerteck to monitor the equipment, record fuel delivery volumes and ensure the fuel treatment rate is within the required specifications.Hand Treatment

Although we will accomodate a customer and allow for hand treatment during an evaluation (when closely monitored), hand treating in real world use is not recommended. Using the two other methods eliminates or substantially reduces human error from the equation and provides a much more consistent treatment rate to the fuel.Ancillary Benefits

The EnerBurn catalyst promotes a more complete fuel burn, the primary benefits of which are increased fuel efficiency and a reduction of emissions. Additionally, EnerBurn usage leads to other ancillary benefits which also benefit you financially in the long run.

- Reduced lube oil consumption

- Increased oil service intervals as a result of cleaner oil

- Cooler operating temperatures will increase useful engine life and lower maintenance costs

- Less emissions means a cleaner workplace environment

- Less emissions means cleaner vehicles, requiring less water and man-hours to clean them

Contact us about pricing to implement EnerBurn® in your fleet

EnerBurn based Products

Industries Currently Served

- Offshore Marine

- Inland Marine

- Waste Hauling

- Over-Road Trucking

- Mining

- Heavy Duty Infrastructure Construction

- Bus Transportation

- Railroad